X-3705 Manual Applied Polyurea Waterproof Coating

Product Info

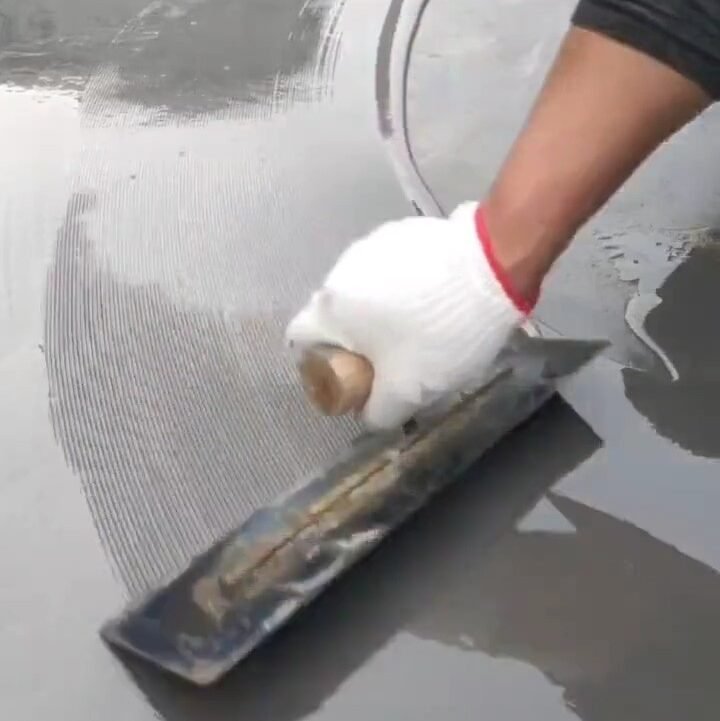

X-3705 redefines manual polyurea application with its solvent-free, odorless formulation designed for complex waterproofing projects. This two-component, high-elasticity coating cures into a seamless membrane with exceptional UV stability and hydrolysis resistance. Engineered for roller/scraper application, it delivers sag-resistant builds up to 1mm per pass – ideal for vertical surfaces, foam substrates, and critical water containment structures.

Key Features

✅ Revolutionary Application Simplicity

- Roller/scraper application – no spray equipment needed

- 30-40 minute pot life (25°C/50% RH) enables precision work

- Self-leveling for pin-hole free finishes

✅ Extreme Performance Elasticity

- >700% elongation at break | 45N/mm tear strength

- Temperature endurance: -60°C to 80°C

- Water absorption: <3% (7-day immersion)

✅ Eco-Safe Formulation

- 100% solids | Zero VOC | Solvent-free

- Compliant with global environmental regulations

✅ Substrate Versatility

- Bonds to foam, concrete, tile & mortar without sagging

- Primer options available for challenging surfaces

The X-3705 polyurea coating is ideal for:

• Foam Surface Protection: Pool floats, insulation layers

• Water Containment: Swimming pools & water parks, Fountain linings & decorative water features

• Architectural Waterproofing: Roof membranes, Bathroom/kitchen wet areas, Underground structures

• Concrete Protection: Parking decks, balconies

Technical Parameters

| Property | Value |

|---|---|

| Gel Time | 20 min |

| Tack-Free Time | 60 min |

| Pot Life | 30-40 min |

| Tensile Strength | >5 MPa |

| Elongation | >700% |

| Tear Strength | 45N/mm |

| Hardness | Shore A 60 |

| Adhesion (concrete) | 2.5 MPa |

Application

Coverage and Application Instructions

1. Surface Preparation

- Clean & dry substrates (moisture <8%)

- Primers:

- Foam: None required

- Concrete/mortar: UTS-1 or US primer

- Tiles: 817 primer

2. Mixing & Application

- Mix Ratio: A:B = 3:1 by weight (7.5kg : 2.5kg per kit)

- Mixing: Pour B into A → mechanical stirring ≤2 minutes

- Work Time: Use within 10 minutes (despite 30-min pot life)

- Film Build: 1mm DFT per 1kg/m² (apply in cross-direction passes)

- Recoat Window: 8 hours @24°C (max 36-hour interval)

3. Environmental Requirements

- Ambient Temp: 5°C–35°C

- Humidity: <80% RH

- Post-Application: Dry for 4 hours before rain exposure