X-3368 Polyurea bed liner

X-3368 Hand-Applied Polyurea Coating | Vehicle Armor & Protective Liner

Product Info

x-3368 hand-applied polyurea bed liner for DIY

Experience the ultimate in surface protection with X-3368, a solvent-free, two-component modified polyurea coating engineered for manual application. This 100% solids formula delivers exceptional strength, flexibility, and resistance, creating a seamless, impenetrable barrier on a variety of substrates.

Designed for applications where spray equipment is impractical, X-3368 is applied with a specialized roller, offering a simple yet robust solution for demanding environments. From vehicle armor to industrial flooring, it provides outstanding protection against abrasion, impact, chemicals, and corrosion, all while being an environmentally friendly, odor-free material.

Key Features & Benefits

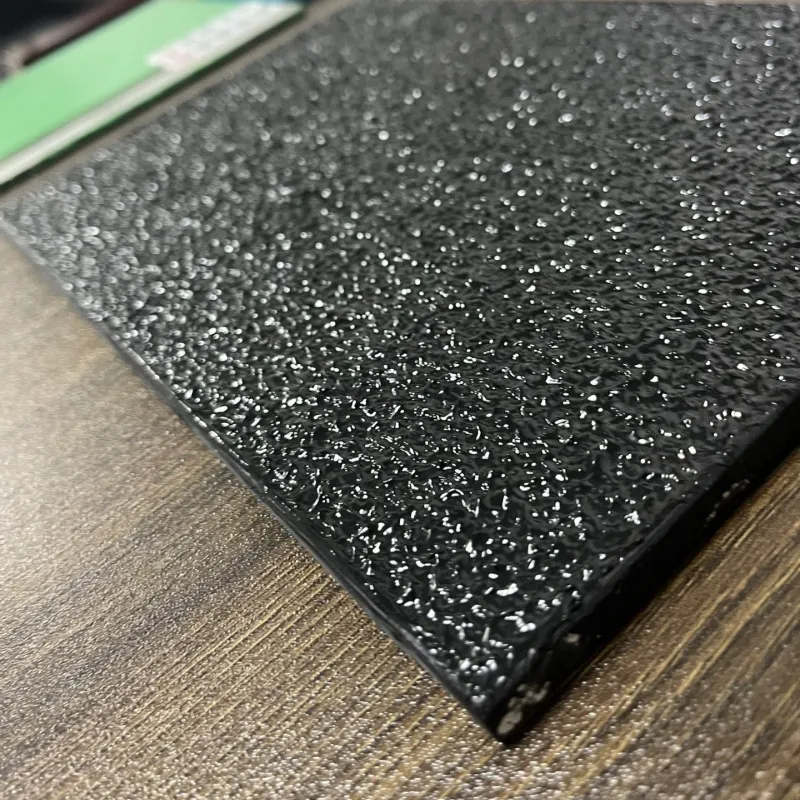

Easy Roller Application: No complex spray equipment needed. X-3368 is designed for straightforward hand-coating, creating a textured, “orange peel” finish for enhanced grip and aesthetics.

Extreme Abrasion & Impact Resistance: With a wear loss of only 50mg (ASTM D4060) and high impact resistance (35.5 J), it is built to withstand heavy mechanical wear, forklift traffic, and tough impacts.

Superior Primerless Adhesion: Bonds directly and tenaciously to properly prepared metal (carbon steel, aluminum, galvanized) and concrete substrates, saving time and material costs.

Unmatched Chemical Resistance: Withstands a wide range of industrial chemicals, including strong acids, alkalis, and salts, making it ideal for containment and processing areas.

100% Solids & Solvent-Free: An environmentally responsible choice with 0 g/L VOCs. It is odor-free during application, making it suitable for indoor or poorly ventilated spaces.

Waterproof & Mold-Resistant: Hydrolysis-resistant for long-term water immersion and formulated to inhibit mold growth in humid environments.

Ideal Applications

X-3368 is the go-to solution for creating durable, protective surfaces across multiple industries:

Vehicle Protection: Truck bed liners, underbody coating, and full-body vehicle armor.

Audio Equipment: Protective coating for speaker cabinets and touring cases.

Industrial & Commercial Flooring: Warehouses, garages, workshops, and areas with heavy forklift traffic.

Marine Applications: Decks, hulls, and areas requiring corrosion and water protection.

Secondary Containment: Chemical storage areas and bunds.

Technical Parameters

| Property | Value | Test Method |

| Mix Ratio (A:B by Weight) | 4:1 | – |

| Pot Life (at 25°C) | > 60 minutes | – |

| Solids Content | 100% (Weight & Volume) | – |

| VOC Content | 0 g/L | – |

| Surface Dry Time (25°C) | < 12 hours | – |

| Full Cure | 3 days (Ready for light use in 24 hours) | – |

| Hardness | Shore D70 | – |

| Tensile Strength | > 20 MPa | ASTM D638 |

| Elongation | 50% | ASTM D412 |

| Adhesion (Steel) | > 10 MPa | – |

| Adhesion (Concrete) | > 2.5 MPa (Substrate Failure) | – |

| Abrasion Resistance | 50mg wear loss (1000 cycles, CS-17, 1kg) | ASTM D4060 |

| Impact Resistance | 35.5 J | ASTM D2794 |

| Application Temperature | -5°C to 38°C | – |

Application Guidelines

Surface Preparation: Ensure the substrate is clean, dry, and free from grease, oil, and loose contaminants. Mechanically abrade concrete to remove laitance. A sealing primer is recommended for damp concrete.

Mixing: Thoroughly stir Component A (colored). Combine Component A and Component B at a 4:1 ratio by weight and mix until a uniform consistency is achieved.

Application: Using a specialized roller, apply the mixed X-3368 to the desired thickness (typically >500 μm). Roll the coating to create the signature orange peel texture before it begins to set.

Curing: The surface will be ready for light traffic after 24 hours. Allow 3 days for a full cure before subjecting the surface to heavy use or chemical exposure. Adhere to the >60 minute working time.