Imitated Wood Polyurethane Foam

PU40 Imitated Wood Polyurethane Foam: Crafting Excellence Beyond Wood

PU40 Imitated Wood Polyurethane Foam is a high-density rigid polyurethane that embodies superior performance as a polymer synthetic material. Injected into molds via a foaming machine, it emerges as a robust solution with remarkable heat and low-temperature resistance. Deformation and cracking are strangers to this foam. Its molding process efficiency and simplicity make it a go-to choice in various sectors, including film and television props, automotive accessories, furniture, decorative materials, and more.

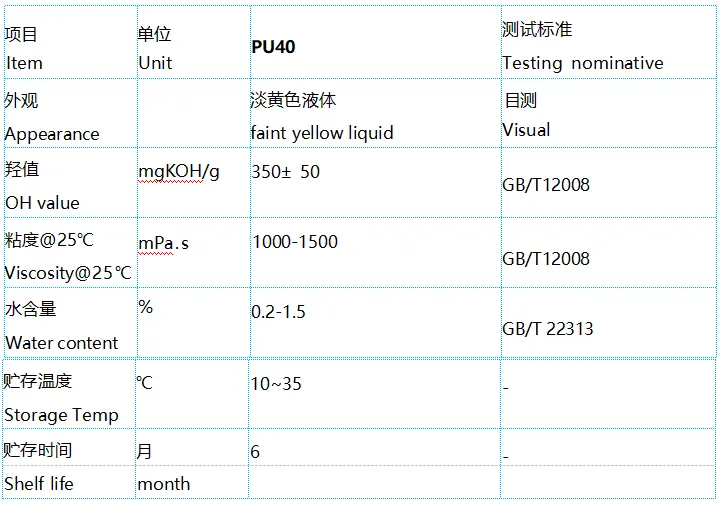

product information

PU40 imitation wood products outshine natural wood in performance. They don’t just imitate wood; they outperform it. Moisture-proof, insect-proof, and immune to cracks and deformation, these foam products bring convenience to processing – planing, nailing, washing, and more. With a tough, smooth, and dense surface, they offer impressive strength, truly resembling natural wood.

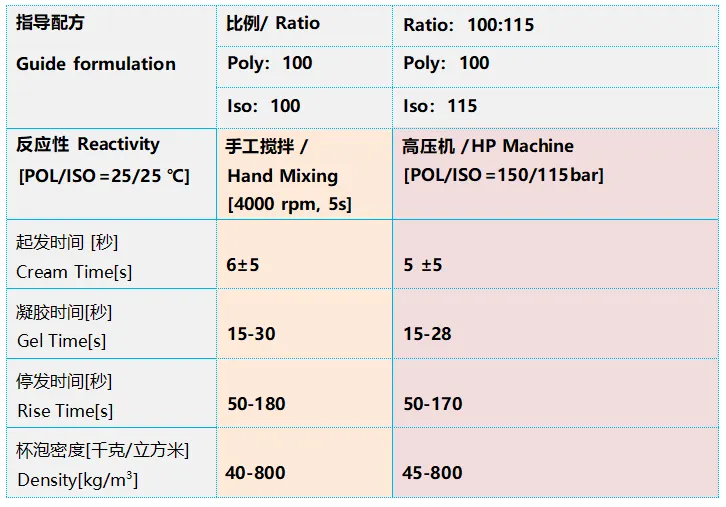

Notable Dosage and Operation:

Medium Hard Wood-like Foam: It expands to about 10 to 15 times its original volume. A kilogram of the combined material foams to around 10 liters. Expect about 100kg of raw materials for a cubic meter of foaming.

High Hard Wood-like Foam: This variant expands to around 5 to 8 times its original volume. A kilogram of combined material yields approximately 5 liters of foam. For a cubic meter of foaming, you’ll need about 200kg of raw materials.

Diverse Applications:

The versatility of PU40 Imitated Wood Foam shines through in its applications. It finds its purpose in film and television props, equipment, simulated plant and animal lining fillers, automotive accessories, furniture, decorative materials, panels, relief frames, and various structural aspects. Its load-bearing capabilities rival natural wood and it excels in performance.

Performance Beyond Wood:

Imitating the warmth of wood, PU imitation wood products elevate the concept. Offering the performance of wood, they surpass it with features like moisture-proofing, insect resistance, crack prevention, and deformation resistance. The convenience of processing, including planing, nailing, and washing, highlights its adaptability. Its smooth, dense, and resilient surface showcases excellent strength, rendering it an ideal replacement for traditional wood materials.

Dosage and Operation:

For medium-hard wood-like foam material, the expansion during the foaming process reaches 10 to 15 times its original volume. A 1kg combination of material yields approximately 10 liters of foam. Similarly, high-hard wood-like foam expands 5 to 8 times, producing around 5 liters from 1kg of combined material. Each cubic meter of foaming necessitates about 100kg to 200kg of raw materials, depending on the desired density.

Operating Guidelines:

At a room temperature of 20℃, the foaming process initiates within about a minute, molding occurs in roughly 5 minutes, hardening takes around 10 minutes, and the demolding process typically concludes within 15 to 20 minutes. Temperature intricacies are crucial; lower temperatures prolong foaming time and influence starting volume.

Optimal Usage:

Minimizing waste is essential. Mix and stir the materials promptly before pouring them into a pre-prepared container. Proper storage maintenance is key; if layering occurs due to prolonged storage, ensure thorough shaking before use to prevent compromised foaming.

Unleash Your Creativity:

Customization is at your fingertips, whether through color paste, spray paint, or acrylic coloring. In instances where the styrofoam adheres to molds, brushing the mold surface with a release agent before demolding ensures a smooth and efficient process.

Imitated Wood Polyurethane Foam

specification