Hot Spray Polyurea for Styrofoam Hard Coating

Hot Spray Polyurea for styrofoam hard coating.

The coating can be sanded

type:C-613

c-613 is hot spray polyurea for styrofoam hard coating, and it can be sanded. Polyurea adheres exceptionally well to various foam types, including expanded polystyrene (EPS), extruded polystyrene (XPS), and polyurethane foam. This versatility makes it an ideal choice for a wide range of projects, whether you’re working with common styrofoam or more specialized foam materials. The strong bond ensures that the protective coating remains intact and effective over time.

- Fast-Curing

- High Flexibility and Durability

- Impact and Abrasion Resistant

- Sandable and Paintable and waterproof

product information

C-613 is a spray-applied polyurea coating designed to be applied using heated dual-component equipment, allowing it to quickly react and form a high-hardness film. X-8586 is available in a flame-retardant version for users to choose from. The flame-retardant version has similar hardness and mechanical properties to the non-flame-retardant version; for more details, please inquire. Compared to traditional polyurea, the X-8586 formula incorporates special ingredients, making the formulation easier to sand, making it more suitable for foam sculpture customers. After curing, this product is almost odorless, unlike traditional polyurea, making it usable indoors or in poorly ventilated areas without any noticeable odor.

Protection: The Ultimate Shield for Your Foam Creations

Polyurea coating offers unparalleled protection for foam sculptures, guarding them against the ravages of weather, water, sun, humidity, and physical damage. This robust defense mechanism significantly extends the lifespan of your artistic or functional foam creations. Imagine a sculpture that retains its pristine condition despite being exposed to torrential rain, blistering sun, or high humidity. Polyurea’s resilient nature ensures that your masterpieces remain intact, preserving the integrity and beauty of your work.

Application Method: Efficiency Meets Precision

When it comes to large foam pieces, the application of polyurea through high-pressure, high-temperature plural component equipment is the most efficient method. The fast-drying nature of polyurea necessitates a method that can keep up with its rapid curing time. Spraying ensures an even coat, covering every nook and cranny of the foam piece, creating a seamless protective layer. This method is not only efficient but also ensures the highest quality finish, essential for large and intricate sculptures.

Properties: The Marvels of Polyurea

Polyurea boasts a range of impressive properties:

- Fast-Curing: With a gel time of just 5-7 seconds, polyurea sets rapidly, making the application process swift and efficient.

- High Flexibility and Durability: Despite its hardness, polyurea remains flexible, accommodating slight movements or shifts without cracking.

- Impact and Abrasion Resistant: This coating can withstand significant physical impacts and abrasions, making it ideal for outdoor and high-traffic areas.

- Waterproof: Complete resistance to water ensures that your sculptures remain unaffected by moisture, whether from rain or humidity.

- Resistant to UV Yellowing: Unlike some coatings, polyurea does not yellow when exposed to ultraviolet light, maintaining its aesthetic appeal over time.

- Sandable and Paintable: Once cured, polyurea can be sanded to achieve a smooth finish and can be painted with various types of paint, offering endless customization options.

Thickness: Customization at Its Best

One of the remarkable features of polyurea is its ability to be applied in unlimited thicknesses. This allows for complete customization based on the project’s specific needs. Whether you require a thin protective layer or a thick, robust coating, polyurea can be tailored to meet those requirements, ensuring that your sculpture has the precise level of protection and finish desired.

Suitable Substrates: Versatility Across Foam Types

Polyurea adheres exceptionally well to various foam types, including expanded polystyrene (EPS), extruded polystyrene (XPS), and polyurethane foam. This versatility makes it an ideal choice for a wide range of projects, whether you’re working with common styrofoam or more specialized foam materials. The strong bond ensures that the protective coating remains intact and effective over time.

Surface Preparation: The Foundation of a Flawless Finish

Proper surface preparation is crucial for the successful application of polyurea. The foam surface should be clean, dry, and free of any debris. This ensures that the coating adheres properly and provides maximum protection. Skipping this step can result in an uneven application or compromised durability, so taking the time to prepare the surface thoroughly is essential.

Finishing: From Sanding to Painting

After curing, the polyurea coating can be sanded to achieve the desired finish. This step allows for the removal of any imperfections and creates a smooth surface ready for painting. Polyurea is compatible with various types of paint, including water-based, oil-based, and automotive paints. This flexibility means you can achieve any look or color scheme you desire, further enhancing the versatility of your foam creations.

Advantages over Other Coatings: Superior Strength

Polyurea is approximately 100 times stronger than some alternative coatings, such as adhesive glue or epoxy. This extraordinary strength makes it the superior choice for protective coatings, especially for projects that require long-lasting durability and resistance to harsh conditions. The robust nature of polyurea ensures that your foam sculptures are well-protected and stand the test of time.

Safety: Non-Toxic but Handle with Care

While polyurea coating is non-toxic and safe for use, proper safety equipment should always be used during application. This includes a respirator, eye protection, and skin protection. These precautions ensure that you can apply the coating safely without risking exposure to harmful fumes or contact with the skin.

Curing Time: Patience Pays Off

The initial set of polyurea occurs quickly, but full curing typically takes 4-5 days at room temperature. During this time, the coated piece undergoes chemical processes that solidify and strengthen the coating. The coated piece can usually be handled after one day of curing at a minimum of 70°F, but allowing the full curing time ensures maximum durability and performance.

Conclusion: Mastering the Application of Polyurea

When considering polyurea for your styrofoam sculpture, remember that proper equipment and technique are crucial for successful application. For smaller projects, hand-brushing or using a small spray gun with cartridges may be suitable, while larger projects typically require a professional-grade spray system. By mastering these techniques, you can ensure that your foam creations receive the ultimate protection and finish, making them stand out and endure for years to come.

Polyurea Coating for Styrofoam

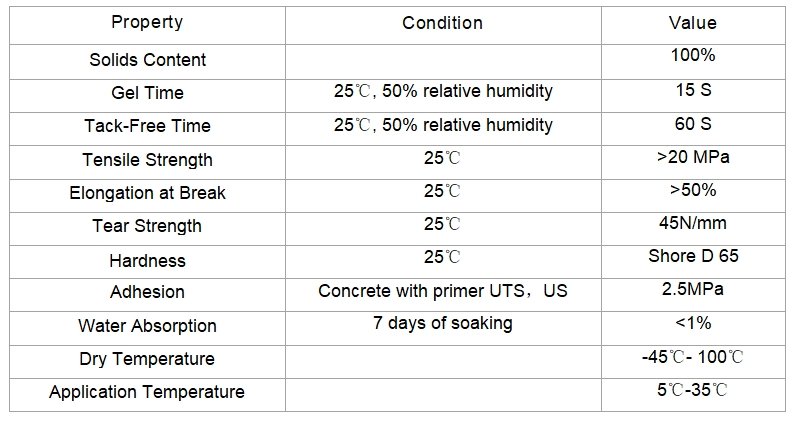

Performance Index

Construction Videos

FAQ

What is C-613?

c-613 is a spray-applied polyurea coating designed for exterior protection of foam sculptures.

Is there a flame-retardant version of C-613?

Yes, C-613 is available in a flame-retardant version with similar hardness and mechanical properties to the non-flame-retardant version.

Can C-613 be sanded?

Yes, C-613 incorporates special ingredients making it easier to sand, suitable for foam sculpture customers.

What is the coverage rate of C-613?

Theoretically, 1 kilogram of X-8586 can cover 1 square meter at a thickness of 1 millimeter, but actual usage should account for a typical loss rate of around 20%.

What packaging options are available for C-613?

C-613 is available in 50-liter pails and 209-liter drums