PU100 Styrofoam Hard Coating

Ideal choice for foam artists seeking a hard-coating solution

Hard Coating for STYRO & eps sculpture

PU100 Foam Sculpture Hard Coating offers a range of remarkable features that make it a standout choice for enhancing foam sculptures. Whether you’re a professional sculptor or a creative enthusiast, these features set PU100 apart:

Discover the revolutionary PU100 Styrofoam Hard Coating, a game-changer for foam artists seeking unparalleled quality and versatility. This exceptional product allows you to apply the coating with ease using a brush, hand spray gun, or our specially designed sprayer. Brush directly onto various surfaces, including EPS, STYROFOAM, XFS, and more, without worrying about any damage to your intricate foam sculptures – PU100 ensures a pristine finish without burning the foam.

product information

- pu100 is a two component polyurethane not a polyurea.

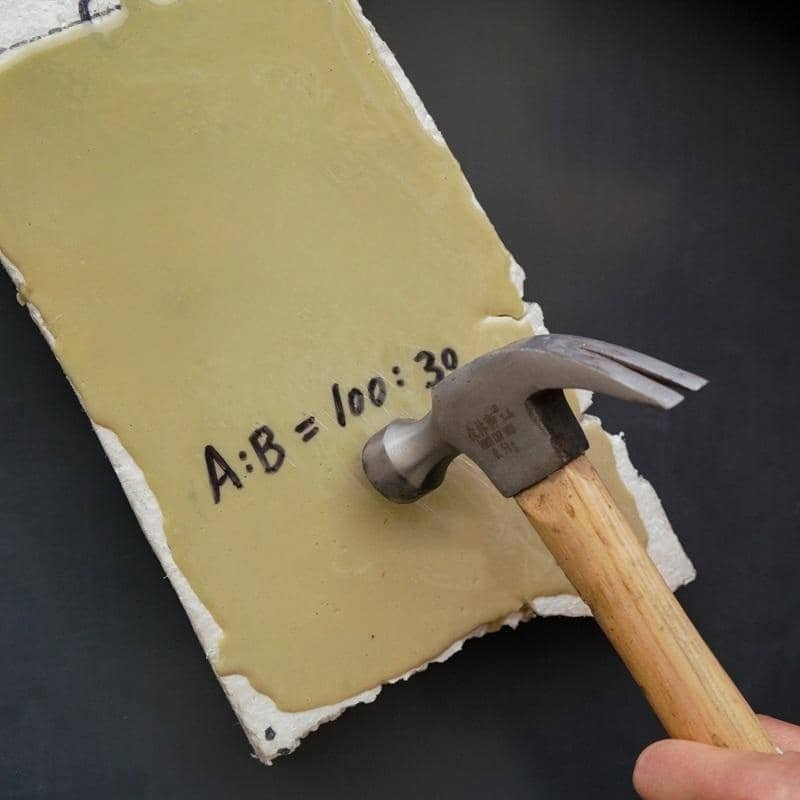

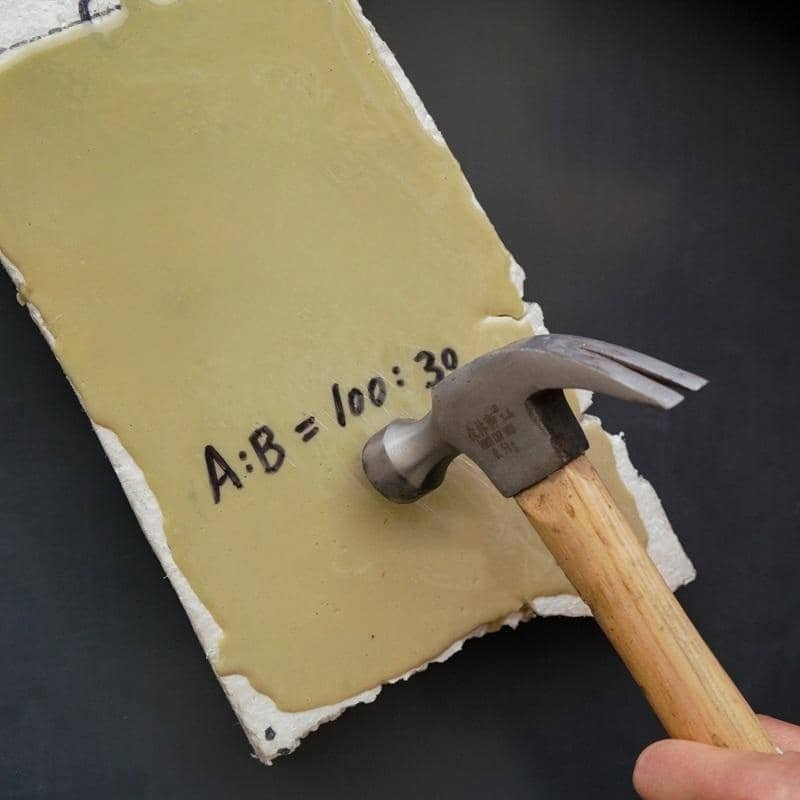

- PU100, a polymer marvel, offers a user-friendly application process. Formulated with advanced materials like polyurethane polyether polyol, it pairs seamlessly with a low-viscosity isocyanate curing agent (B material). Unlike solvent-based options, PU100 is foam-friendly, eco-friendly, achieving FRP-level hardness upon curing.

- The A and B components combine to create a solvent-free coating with remarkable hardness and temperature resistance. Application is simple – brush it generously onto foam surfaces to enhance strength for easy transport without causing any harm. PU100 supports layering without delamination, preserving authentic sculpting effects and leaving the foam unharmed. Elevate your foam artistry with PU100’s unparalleled features.

what makes us different

The Features

PU100 Styrofoam Hard Coating

1. Easy to be Applied

⭐PU100 Can be Applied with a brush, hand spray gun, or our specialized sprayer.

⭐Unleash your creative prowess with ISO & POLYOL's groundbreaking product – PU100 Styrofoam Hard Coating. Crafted with foam artists in mind, this versatile coating offers a seamless application process. Whether using a brush, hand spray gun, or our purpose-built sprayer, you can bring your artistic visions to life effortlessly.

2. Easy Sanding

⭐Once cured, PU100 is easy to sand and does not produce a lot of fumes.

(Wear a mask when sanding)

⭐Boost your efficiency and bottom line with PU100's unique attributes. By reducing processes and production labor, you not only cut costs but also deliver more affordable products to your customers, positioning yourself competitively in the market.

what makes us different

Other Features

Achieve Fiberglass-Like Hardness

The recommended 1mm-2mm thickness of PU100 ensures your foam sculptures achieve the hardness of fiberglass. Make your creations durable and long-lasting with PU100 Foam Hard Coating.

Create Safely with PU100

PU100 Foam Hard Coating is a non-toxic, odorless, and non-flammable material, ensuring a safe and pleasant working environment. Dive into your foam carving projects without any worries – the perfect blend of safety and creativity.

Cover More, Save More

1.2kg Covers 1 Square Meter at 1mm Thickness Get more out of every application! With PU100, 1.2kg covers an entire square meter at a 1mm thickness. Achieve outstanding results while minimizing material usage – cost-effective and high-quality foam coating, all in one!

Bonding Brilliance

PU100 Bonds Well to Putty and Paint Experience seamless bonding! PU100 bonds exceptionally well to putty and paint, eliminating the need for a prime coating. Save time and effort while achieving a flawless finish on your foam creations.

Surface Compatibility

Brush directly onto EPS, STYROFOAM, XFS, and other foam carving surfaces without causing any damage.

Efficiency and Affordability

Streamline your creative process by reducing production processes and labor, making your products more competitively priced.

Demo Videos

FAQ

What is PU100 Styrofoam Hard Coating?

PU100 Foam Hard Coating is a polymer material specifically designed for hardening and coating foam sculptures.

What are the main components of PU100?

PU100 consists of polyurethane polyether polyol and a low-viscosity isocyanate curing agent, making it a two-component polymerization coating.

How does PU100 enhance foam sculptures?

PU100 increases the strength of foam sculptures, providing a real sculpting effect without causing delamination.

Is PU100 environmentally friendly?

Yes, PU100 is solvent-free and environmentally friendly, making it a safe option for foam coating.

Can PU100 be directly applied to foam surfaces?

Yes, PU100 can be directly brushed onto the surface of foam sculptures without the need for professional spraying equipment.

What is the recommended thickness for better strength?

It is recommended to brush on PU100 at a 2mm thickness for improved strength.

How long can PU100-coated foam sculptures last outdoors?

PU100-coated foam sculptures can withstand outdoor conditions for up to 5 years with a 2mm thickness.

How is PU100 applied to foam sculptures?

PU100 is applied by hand brushing after fully mixing A and B components in a 3:1 ratio by weight.

Can PU100 be applied on damp surfaces?

No, the surface should be clean and dry to avoid air bubble formation during application.

Is professional spraying equipment necessary for PU100 application?

No, PU100 is designed for easy hand operation and does not require professional spraying equipment.

What safety precautions should be taken when using PU100?

Safety precautions include using goggles and rubber gloves to avoid skin or eye contact with component B.

How long is the operation time for PU100 at different temperatures?

At approximately 25℃, the operation time is about 10 minutes, and at 8℃, it extends to about 20 minutes.

Can PU100 be applied indoors as well?

Yes, PU100 is suitable for both indoor and outdoor foam sculptures, providing durability and protection.

How are A and B components measured during mixing?

A and B components are measured by weight ratio using electronic scales to ensure accurate mixing.

What is the shelf life of PU100?

One Year, and Keep the components sealed and stored in a cool place.Long-term storage of material A will precipitate, need to be shaken before use. material B will not precipitate.

Material curing time

20 minutes material does not flow, 2 hours TRACK FREE, 12-24 hours fully cured.