X-8190 Abrasion & Chemical Resistance Polyurea Coating

Industrial-Grade Protection for Extreme Environments

Product Info

X-8190 is a two-component, solvent-free polyurea coating engineered for rapid curing and unmatched durability. With a 5-second gel time at 70°C, it combines high surface hardness (Shore D53), 180% elasticity, and exceptional resistance to abrasion, chemicals (30% H₂SO₄, 15% HCl, 30% NaOH), and prolonged water immersion. Its fast cure (15-second surface dry) and waterproof properties make it ideal for high-traffic industrial assets

Critical Defense Against Damage

- Military-Grade Durability: 160 inch-lb impact resistance and 115 kN/m tear strength.

- Chemical Immunity: Resists acids, alkalis, oils, and mold in humid environments.

- Thermal Flexibility: Performs from -50°C to 100°C with zero hardening or dripping.

- Superior Adhesion: 2.5 MPa on primed concrete (causes concrete failure) | 14 MPa on unprimed steel.

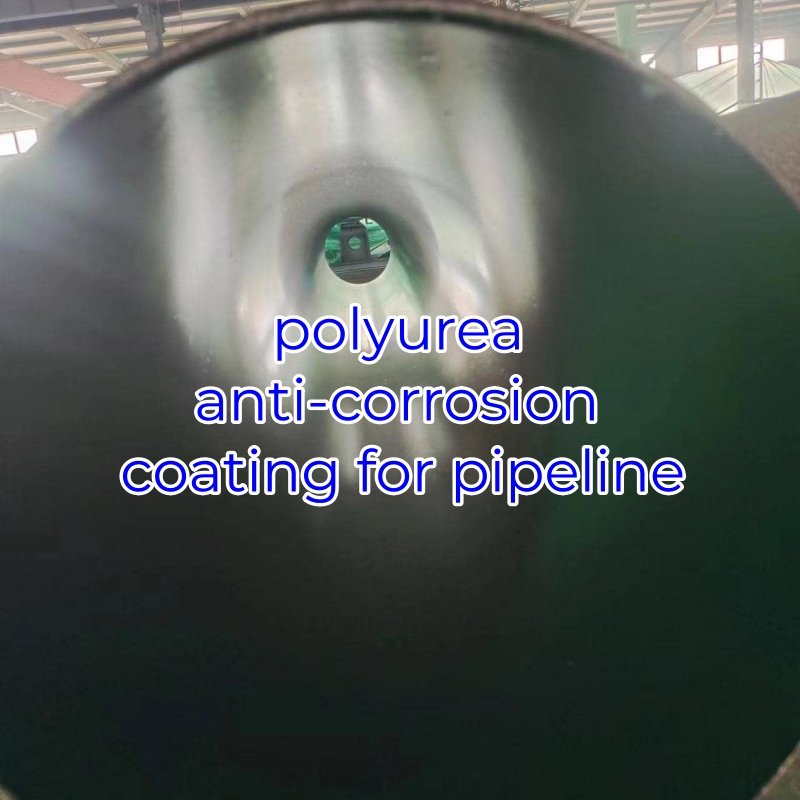

The X-8190 polyurea hard coating is ideal for:

- Vehicle Protection: Chassis, truck beds, body armor.

- Critical Infrastructure: Oil/gas tank linings (internal/external), acid/alkali storage tanks.

- Industrial Flooring: Parking lots, manufacturing plants, waste facilities.

- High-Abuse Zones: Container floors, garbage pits, power plant platforms

Technical Parameters

| Property | Value |

|---|---|

| Gel Time | 5 seconds (at 70°C) |

| Surface Dry Time | 15 seconds |

| Full Cure Time | 90% in 24 hours |

| Tensile Strength | 21 MPa |

| Elongation at Break | 180% |

| Tear Strength | 115 kN/m |

| Hardness Shore | D53 |

| Water Absorption | <2.5% (7-day immersion) |

| Water Impermeability | 0.4MPa/4hrs |

| Operating Temperature | -45°C to 100°C |

| Solids Content | 98% |

Application

Coverage and Application Instructions

- Surface Prep: Remove grease/contaminants; concrete requires UTS-1/302 primer.

- Spray Parameters: 60-70°C heater temperature | 2000 PSI equipment.

- Environmental Limits: Max 85% humidity | Substrate temp 10-38°C.

- Anti-Slip Option: Apply quartz-sand topcoat for textured surfaces