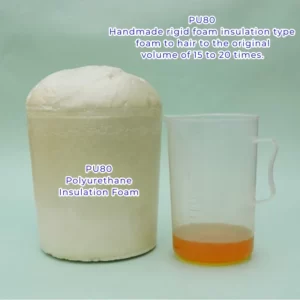

Polyurethane Insulation Rigid Foam PU80

Versatile Polyurethane Insulation Rigid Foam Composite Material

5/5

Polyurethane insulation rigid foam combination material is a game-changer, in the world of film and television prop production, crafts creation, and insulation solutions.

Its applications span from filling and thermal insulation to crafting film props, refrigeration units, and more. This closed-cell rigid foam stands out for its impressive thermal insulation performance and user-friendly features.

Polyurethane Insulation Rigid Foam information

Key Characteristics:

- Thermal Insulation Expertise: The closed-cell rigid foam brings forth outstanding thermal insulation properties, making it an ideal choice for applications in refrigerators, freezers, and even water heaters.

- User-Friendly Flexibility: This foam material is surprisingly easy to work with. You can even pinch it with your hand force, showcasing its pliability.

- Crafting and Bonding: From model-making to bonding benzene boards and sculptures, the closed-cell rigid foam’s versatility is evident. It’s perfect for various creative projects.

- Steady Performance: With a solid bonding capacity with materials like cement, wood, metal, glass, and plastic, it seamlessly fits into various building and construction projects.

- Water-Resistant Floatation: Its closed-cell structure ensures it doesn’t absorb water and can even float on the water surface.

- Room for Expansion: The foam can expand to an impressive 15 to 20 times its original volume when exposed to air.

- Easy Mixing and Molding: Mix the two materials in a 1:1 weight ratio, watch them blend, and then pour into your desired container for gradual foam molding.

- Quantity and Expansion: When a kilogram of combined material foams, it can expand up to about 15 liters.

- Temperature Influence: Temperature has a significant impact on foam stability, expansion time, and curing. Lower temperatures result in a slower expansion and smaller volume.

- Challenges in Storage: The B material might show inflation in high temperatures or when shaken. If stored for long periods, proper shaking is essential to avoid uneven foaming.

Usage Guide:

- Mix the two materials in a 1:1 weight ratio until well-blended.

- Pour the mixture into your intended container for gradual foam molding.

- The material expands around 15 to 20 times its original volume.

- Foam molding takes about 3 minutes at 20°C, and it hardens in around 10 minutes.

- Note that temperature affects foaming volume and timing.

Tips for Best Results:

- In hotter temperatures, the B material might inflate. Cooling it down and gently releasing pressure will help.

- Be cautious with B material exposure to air; it can clump. After use, seal it properly.

- If there’s layering due to storage, shake the white material well before use.

- For coloring, you can add color paste or opt for post-foaming painting or acrylic coloring.

- If foam sticks to the mold, applying a mold surface release agent can help with demolding.